Explore Affordable Heavy Equipment Forklift Rentals in Wollongong for Local Businesses

Written By : Darko

Finding affordable heavy equipment and forklift rental in Wollongong requires clear comparisons, realistic pricing expectations, and a practical plan for site logistics. This article explains the primary rental options, from electric forklifts for indoor warehouses to rough-terrain telehandlers for construction sites, and shows how to match machine capabilities to your operational needs while keeping costs predictable. Local businesses will learn the factors that drive rental rates, the advantages of short-term versus long-term hire, and which industries benefit most from different machine classes, helping managers choose the right lift for safety and productivity. Practical steps to request a quote and what typical rental agreements include are laid out so you can move from planning to hire quickly and confidently. Throughout, the focus is on heavy equipment and forklift hire in Wollongong and the Illawarra, using current market context and operational guidance to reduce selection risk and control costs.

What Types of Forklifts and Heavy Equipment Can You Rent in Wollongong?

Equipment hire for material handling covers several machine classes designed to meet different lift capacities, site conditions and regulatory needs. Understanding each type’s core capability, fuel or power source, and ideal application reduces downtime and improves operator safety, which in turn lowers total project cost. Below are the main categories available for hire in Wollongong and short notes on suitability to guide selection; the following subsection then details fuel variants and the secondary categories used for site access and internal handling. Choosing the right machine begins by matching lift capacity, mast type and mobility to the task, which leads naturally to model and fuel-type decisions.

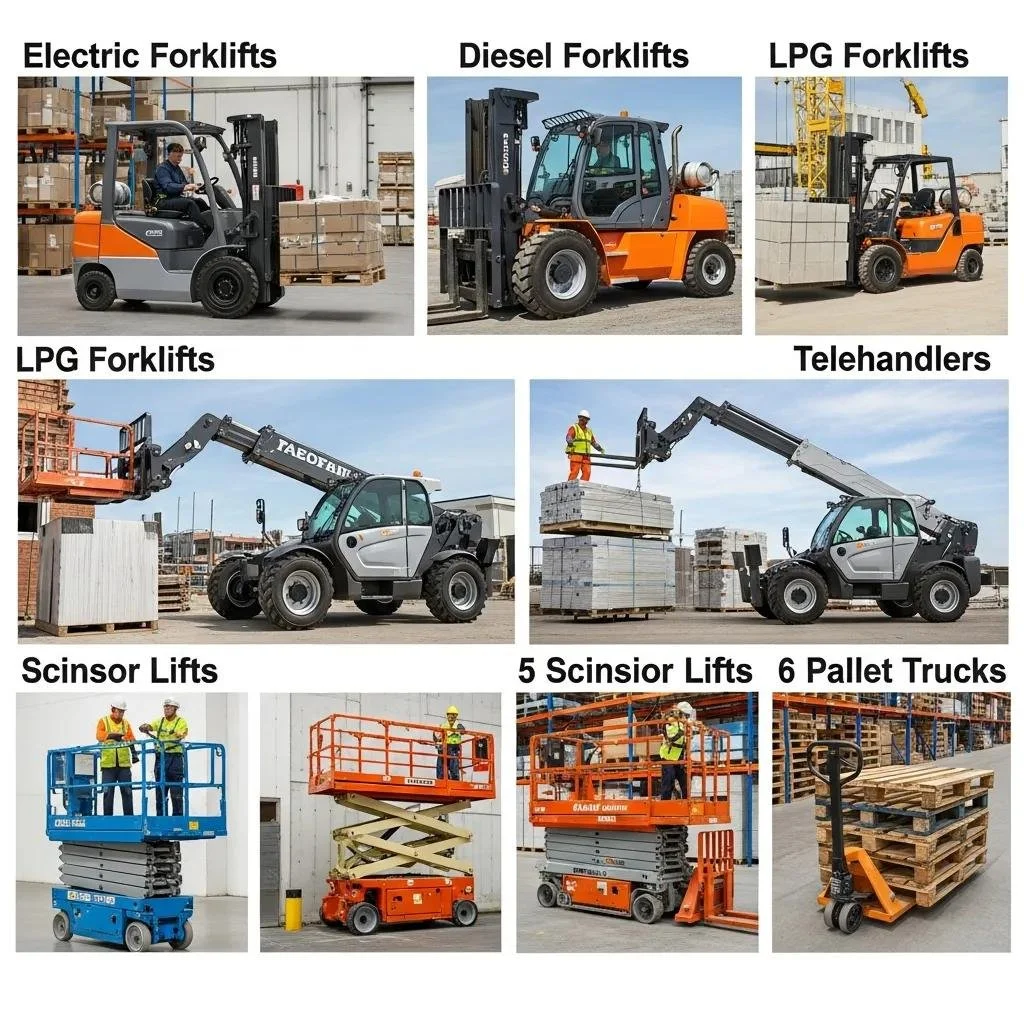

Available equipment types and quick suitability notes:

Electric forklifts: Best for indoor warehousing and areas with low-emission requirements.

Diesel forklifts: Suited to outdoor, heavy-duty lifting and rough surfaces.

LPG (liquid petroleum gas) forklifts: Flexible indoor/outdoor option with quick refuel times.

Telehandlers: Ideal for lifted loads at a distance on construction and agricultural sites.

Scissor lifts: Provide safe vertical access for maintenance, trades and installation work.

Pallet trucks and walkie stackers: Efficient for internal pallet movement and order picking.

These categories provide a starting point for assessing lift capacity and operational constraints, and the next subsection explains the primary fuel and power variants to help you choose the best fit.

Which forklift models are available for hire: electric, diesel, and LPG options?

Electric forklifts are the preferred choice for indoor operations because they produce no local exhaust emissions, have lower noise levels and typically require less day-to-day mechanical maintenance than combustion engines. This makes them ideal for warehouses, cold stores and retail backrooms where ventilation is limited and operator comfort matters, and modern electric units often match diesel capacity up to medium-duty ranges. Diesel forklifts deliver higher torque and sustained power for outdoor work, heavy lifting and rough-terrain applications, making them appropriate for construction yards and bulk handling; they require adequate ventilation and are best when used outdoors. LPG forklifts present a compromise: they deliver combustion power with lower particulate emissions and faster refueling than diesel, so facilities that mix indoor and outdoor operations sometimes prefer LPG for operational flexibility.

These fuel and power choices determine the likely maintenance cadence and on-site support requirements, which in turn affects rental terms and cost estimates, so assessing site constraints leads naturally to comparing rental pricing structures.

What other heavy equipment rentals do we offer: telehandlers, scissor lifts, and pallet trucks?

Telehandlers extend reach and handling versatility by combining a lifting carriage with boom reach, enabling loaders to place pallets or materials at height or over obstacles on construction and farming sites; they are chosen when reach and terrain adaptability matter. Scissor lifts provide a stable, vertical platform for tradespeople performing electrical, HVAC or façade work and are rated by platform height and safe working load; they reduce the need for scaffolding when short-duration elevation access is required. Pallet trucks and walkie stackers streamline internal material flow by enabling safe, quick pallet movement and order fulfilment in confined aisles, improving throughput in warehouses and retail environments.

Selecting from these categories depends on task duration, working height, site access and permitted load, evaluating those parameters narrows the options and informs a tailored rental enquiry to secure the right machine for your schedule and site conditions.

| Equipment Type | Typical Lift Capacity | Ideal Application | Indoor / Outdoor Suitability |

|---|---|---|---|

| Electric Forklift | 1–5 tonnes | Warehousing, retail, cold storage | Indoor primary, outdoor limited |

| Diesel Forklift | 2–16+ tonnes | Construction yards, heavy loading | Outdoor primary |

| LPG Forklift | 1–5 tonnes | Mixed indoor/outdoor operations | Suitable both, with ventilation caveats |

| Telehandler | 2–12 tonnes (reach variable) | Construction, agriculture, site lifting | Outdoor, rough terrain capable |

| Scissor Lift | Platform heights 3–20 m | Trades, maintenance, installations | Indoor/outdoor depending on model |

| Pallet Truck / Walkie | 1–2.5 tonnes | Order picking, short transfers | Indoor primary |

This equipment comparison clarifies capacity and environment fit, helping procurement teams shortlist machines before requesting detailed hire quotes from providers in the Wollongong area.

How Does Wollongong Forklift Ensure Affordable and Flexible Rental Rates?

Rental affordability depends on transparent pricing components, efficient logistics and flexibility in hire terms that match project timelines; these elements together reduce total cost of ownership for rented equipment. Key pricing drivers include the machine class, hire duration, delivery distance, required attachments and the level of maintenance or breakdown support bundled into the agreement. By structuring day, week and month options and offering tiered support, providers can reduce effective hourly costs for long projects while still accommodating short-term spikes in demand. The following bullets summarise typical pricing factors and a sample pricing table demonstrates illustrative duration-based ranges to set realistic client expectations.

Academic studies further explore sophisticated frameworks for optimising rental equipment profit and performance, especially when faced with operational uncertainties and varying maintenance conditions.

Optimising Rental Equipment Profit & Performance Under Uncertainty

Most existing research on rental and leased equipment relies on idealised assumptions, often overlooking operational uncertainty and limited information sharing between owners and users. To address these limitations, this paper proposes a bi-objective fuzzy probabilistic framework aimed at optimising profit allocation between two echelons of a rental-based supply chain. The approach incorporates system stochastic fluctuations and introduces fuzzy parameters to more accurately reflect real-world uncertainties in maintenance and usage conditions. A sensitivity analysis is conducted to evaluate the influence of rental parameters on both echelon-level and overall supply chain performance. This framework offers a robust and practical decision support tool for rental systems under uncertainty.

Decision-Making in Rental Manufacturing Equipment Under Imprecise Information Sharing: A Bi-objective Fuzzy Probability Combined Approach: M. Haoues et al., M Haoues, 2025

Primary factors that influence forklift rental pricing:

Equipment specification and lift capacity: Higher-capacity or specialised attachments increase base rates.

Hire duration and commitment: Longer contracts usually reduce daily rates and secure machine availability.

Delivery, pickup and maintenance: Logistics and included service levels affect total rental cost.

Wollongong Forklift implements competitive pricing, flexible rental options and local support to keep hire cost-effective for Illawarra businesses, emphasising local expertise and comprehensive equipment choice to match projects efficiently.

| Duration | Typical Daily Range (AUD) | Typical Weekly Range (AUD) | Included Services |

|---|---|---|---|

| Short-term (1–7 days) | 120–450 | 600–2,000 | Basic delivery within region, standard maintenance |

| Medium-term (1–4 weeks) | 90–350 | 450–1,500 | Priority servicing, flexible pickup dates |

| Long-term (1+ months) | 60–250 | 250–1,000 per week equivalent | Scheduled maintenance, discounted rates |

This sample pricing table shows how duration and service inclusions change effective cost; negotiating duration and maintenance scope is the primary way to achieve affordability and predictability for larger projects.

What factors influence forklift rental pricing in Wollongong?

Several cost drivers determine the rental rate you will be quoted, and understanding them lets you optimise the hire package for value rather than just lowest headline price. Equipment size and lift capacity determine the base rate because higher-rated machines have larger capital and operating costs, while specialised attachments such as side-shifters, rotators or long forks add daily surcharges. Logistics such as delivery distance from the depot, required time windows for drop-off and site access constraints can raise transport costs; likewise, including scheduled maintenance and breakdown support in the rental creates higher but steadier expense profiles. Seasonality and local demand spikes, especially during construction peaks, also alter availability and rates, so planning and flexible scheduling can yield significant savings.

Managing these factors through clear specifications and realistic lead times reduces unexpected surcharges and improves uptime, which naturally leads into a comparison of short-term versus long-term hire benefits.

How can businesses benefit from short-term and long-term hire options?

Short-term hire provides rapid capacity to cover project peaks, seasonal demand or emergency equipment failures without long-term capital commitment, making it ideal for one-off lifts, event setups and testing new workflows. Businesses gain flexibility to scale without depreciation concerns, and for brief projects the total cost often remains lower than purchasing. Long-term hire reduces effective monthly costs through rate discounts, provides predictable budgeting and keeps fleet flexibility high; it can be preferable for contractors or sites with sustained but non-permanent requirements. Combining short and long hires in a mixed strategy, using long-term units for baseline capacity and short-term hire to manage spikes, optimises both cost and availability for many operational scenarios.

Short-term hire is best for emergency cover, testing equipment suitability and peak workloads.

Long-term hire offers lower monthly costs, predictable budgeting and reduced procurement overhead.

Hybrid strategies combine baseline long-term capacity with short-term spikes to optimise cost and uptime.

These trade-offs frame the decision process when selecting a supplier that can provide flexible terms and consistent local support.

Why Choose Wollongong Forklift for Your Heavy Equipment Rental Needs?

Choosing a supplier with local knowledge and a comprehensive fleet reduces selection risk and improves ongoing uptime, particularly for businesses operating in Wollongong and the wider Illawarra. Key decision criteria include the breadth of available machines, responsiveness for servicing and delivery, transparent pricing and a willingness to tailor hire terms to project schedules. Wollongong Forklift positions itself around several unique value propositions, local expertise, comprehensive range, competitive pricing, flexible rental options and strong customer support, which together reduce downtime and simplify procurement decisions for customers.

Wollongong Forklift’s local presence in the Illawarra allows faster response times for delivery and maintenance, helping projects recover quickly from unexpected breakdowns and minimising onsite delays.

What local expertise and customer support does Wollongong Forklift provide?

Local expertise means an understanding of regional site conditions, common load profiles and permit requirements that helps match equipment precisely to your job; suppliers with local knowledge can recommend suitable mast heights, tyre types and attachments to fit both site and regulation. Wollongong Forklift offers end-to-end assistance from equipment selection to delivery and scheduled servicing, reducing coordination overhead for site managers who need a single point of contact for hire logistics. Rapid local response also shortens downtime when call-outs are needed and simplifies inspections or site assessments before delivery. This local service approach ensures that operational constraints are considered early in the hire process, which improves machine uptime and project predictability.

Clear local processes and defined support workflows make it easier to plan operations and provide peace of mind when equipment becomes mission-critical, which ties directly into pricing benefits next.

How does competitive pricing and comprehensive equipment range benefit customers?

A broad fleet combined with competitive rates means customers can select right-sized machines rather than over-specifying and paying for unnecessary capacity, which directly reduces operating hours and fuel or energy consumption. Competitive pricing coupled with transparent inclusions, like scheduled maintenance, reduces hidden costs and simplifies budgeting for long-term projects, while access to specialised attachments prevents expensive workarounds. By offering flexible hire options, Wollongong Forklift helps businesses scale capacity according to project phases, avoiding capital purchase and depreciation.

Matching the right machine at the right price shortens project timelines and reduces total cost of operations, leading naturally into the discussion of which industries most benefit from these hire options.

Local expertise: Faster delivery and tailored equipment recommendations.

Comprehensive fleet: Right-sized machines and attachments reduce over-specification.

Competitive pricing: Transparent inclusions and flexible terms improve budgeting.

These practical advantages explain why choosing a local, full-service hire partner matters for Wollongong projects.

What Are the Ideal Applications and Industries for Forklift and Heavy Equipment Hire in Wollongong?

Different industries require different machine characteristics, and rental provides a cost-effective way to access specialised equipment only when projects demand it. Common sectors that benefit from hire include construction, warehousing and logistics, manufacturing, retail distribution and agriculture, each requiring distinct lift capacities, access equipment and handling speeds. Selecting the right equipment for the industry application reduces unnecessary downtime and safety risks while improving throughput or job completion times. The following list ties equipment types to industry scenarios to help planners map needs quickly and prepare a targeted rental specification before contacting suppliers.

Construction: Telehandlers and rough-terrain forklifts for material placement and site logistics.

Warehousing & Logistics: Electric forklifts and pallet trucks for order fulfilment and stock movement.

Manufacturing: Diesel or electric forklifts with specialised attachments for handling raw materials.

Retail & Distribution: Pallet trucks and compact electric units for tight aisles and back-of-house handling.

Events & Maintenance: Scissor lifts for temporary elevated access during installations or maintenance.

These mappings guide machine selection for site-specific requirements and lead into a closer look at the advantages of electric forklifts for eco-sensitive and indoor operations.

Which industries benefit most from forklift and telehandler rentals?

Construction sites regularly use telehandlers and rough-terrain forklifts because these machines combine lift capacity with mobility across uneven ground, enabling material placement at height without permanent machinery ownership. Warehousing and logistics operations favour electric forklifts and pallet trucks to support high-frequency internal movements and maintain indoor air quality and noise levels that improve worker safety and comfort. Manufacturing plants typically require a mix of diesel and electric units, sometimes with specialised attachments, to handle diverse material types and adapt to production changes without capital expenditure. Event organisers and maintenance teams commonly hire scissor lifts for short-term elevated access where scaffolding would be inefficient, and agricultural operations benefit from telehandlers for loading, stacking and reach tasks.

Understanding sector-specific demands simplifies the rental conversation and ensures the hired machine matches both operational tempo and site constraints, which brings us to the environmental and operational case for electric forklifts.

How do electric forklifts support eco-friendly and indoor operations?

Electric forklifts contribute to reduced onsite emissions and lower noise pollution, which improves air quality and operator comfort in enclosed spaces like warehouses and cold stores, and lessens ventilation requirements compared with diesel alternatives. Operationally, electric units can have lower running costs due to fewer moving parts and reduced fuel expenses when charged from efficient power infrastructure, while modern battery management and quick-change systems support sustained shift work. These advantages make electric forklifts attractive for food handling, pharmaceutical storage and retail environments where contamination risk and worker wellbeing are priorities. Selecting electric models for indoor use often requires assessing charging infrastructure, battery swap procedures and duty cycle compatibility to ensure continuous operations.

Further research emphasises the critical role of electric forklifts in achieving sustainable logistics and optimising energy use, particularly through advanced recharging strategies.

Optimising Electric Forklift Performance & Recharging Strategies

1. The increasing impacts of climate change and global warming, highlighted by recent widespread natural disasters, underscores the urgent need to shift to sustainable business models across all industries. Supply chains contribute to approximately 50% of global CO2 emissions, with logistics ranking among the three most impactful activities. This highlights the critical need to decarbonise the logistics sector through the electrification of freight transportation and the adoption of green warehousing practices. There is yet a significant gap in the literature in some of its core aspects such as electric vehicle recharging exploiting facilities’ on-site photovoltaic (PV) renewable energy production. The objective of this master’s thesis is to fill this gap by defining a structured approach to identify optimal electric vehicle recharging strategies and to develop an optimisation model applicable to a wide range of logistic facilities. To achieve this result, a warehouse with

Optimising the economic and environmental performance of electric trucks and forklifts in the logistics sector: exploring the impact of opportunistic recharging …, 2023

These environmental and operational benefits inform the procurement decision and naturally lead to a clear process for obtaining quotes and understanding rental contract terms.

How Can You Get a Quote and What Are the Rental Terms for Heavy Equipment in Wollongong?

Requesting a quote and understanding rental terms should be a straightforward, stepwise process that reduces friction and sets clear expectations for delivery, maintenance and liability. A concise quote workflow helps buyers compare options quickly, while a transparent outline of rental agreement clauses, period, deposit, insurance, damage policy and maintenance responsibilities, reduces later disputes. The table below summarises the expected quote process, lead times and what maintenance coverage typically includes so procurement teams can plan accordingly. After the table, precise actionable steps show how to request a tailored quote and what documentation or site information to prepare.

| Process Step | Typical Lead Time | What to Expect |

|---|---|---|

| Initial enquiry and specification | 1–2 business days | Request for capacity, site access, dates and attachments |

| Availability check and tailored quote | 1–3 business days | Itemised rate by duration, delivery cost and service inclusions |

| Confirmation and deposit | Same day – 3 days | Booking confirmation, delivery scheduling and deposit terms |

| Delivery and setup | 1–5 business days | Onsite delivery, operator briefing and handover checklist |

This structured process clarifies timelines and responsibilities and helps avoid last-minute surprises when coordinating project schedules.

What is the process to request a free quote for forklift hire?

To request a tailored quote, prepare a concise brief that includes the required lift capacity, proposed hire dates, site address and any special attachments or access constraints, and then submit this information through the provider’s enquiry channels or by phone for quicker response. Expect an initial availability check followed by a detailed, itemised quote with daily, weekly and monthly pricing options and specified inclusions such as delivery window and basic maintenance. Typical response times range from same-day for simple enquiries to a few days for complex site assessments or specialised equipment. Having clear site photos and load specifications ready accelerates the process and reduces the need for follow-up questions.

Providing precise project details at enquiry reduces lead time and ensures the supplier can match the correct machine and service level, which ties directly into the contractual terms you will negotiate next.

| Quote Element | Attribute | What to Expect |

|---|---|---|

| Response time | From enquiry to quote | 1–3 business days depending on complexity |

| Documentation | Required information | Site address, lift capacity, access constraints, hire dates |

| Acceptance | Confirmation process | Booking deposit or signed hire form, delivery scheduling |

This summary clarifies the administrative steps and helps you prepare a complete request that shortens the procurement timeline.

What are the typical rental agreement terms and maintenance support included?

Standard rental agreements typically specify the hire period, invoicing cadence, required security deposit or payment terms, insurance expectations and damage or loss responsibilities, and customers should review these clauses carefully before signing. Maintenance coverage varies by provider and can include scheduled servicing, roadside or breakdown call-outs and replacement equipment during extended repairs; contracts may offer maintenance-inclusive tiers or charge on-demand service rates. Cancellation and extension policies define how schedule changes are handled and whether early termination fees apply, so building flexibility into the contract is important for project variability. Suppliers often offer additional operator training or onsite assessment services as optional inclusions to ensure safe, compliant operation.

Knowing these typical clauses and service options in advance enables clearer negotiations and ensures the rental agreement aligns with your risk tolerances and operational needs.

Prepare project details: lift capacity, dates, site access and attachments to expedite accurate quotes.

Request itemised pricing: daily, weekly and monthly rates with included services to compare offers.

Confirm terms in writing: delivery, maintenance and liability clauses to avoid misunderstandings.

| Agreement Item | Typical Inclusion | Customer Action |

|---|---|---|

| Maintenance | Scheduled servicing + emergency call-outs options | Decide on maintenance-inclusive tier |

| Insurance & liability | Customer typically responsible for insurance unless otherwise agreed | Confirm insurance coverage prior to hire |

| Delivery & pickup | Regional delivery windows, potential surcharge for remote sites | Provide accurate site access details |

This final table helps clarify typical contractual elements so procurement can finalise hire with confidence.

For enquiries specific to Wollongong and the Illawarra region, you can request a quote by calling (02) 4288 1513 or by using the equipment enquiry form available via Wollongong Forklift contact channels; including precise dates, site location and capacity needs speeds a tailored response.